About us

With over 40 years of expertise, CAM Bioceramics specializes in developing and manufacturing calcium phosphate solutions tailored to meet your needs for implant coatings, joint replacements, spinal implants, bone void fillers, and resorbable fixations. As a trusted partner to leading global companies in the industry, we are committed to upholding the highest quality standards, enabling our customers to improve lives.

Our solutions for medical implants

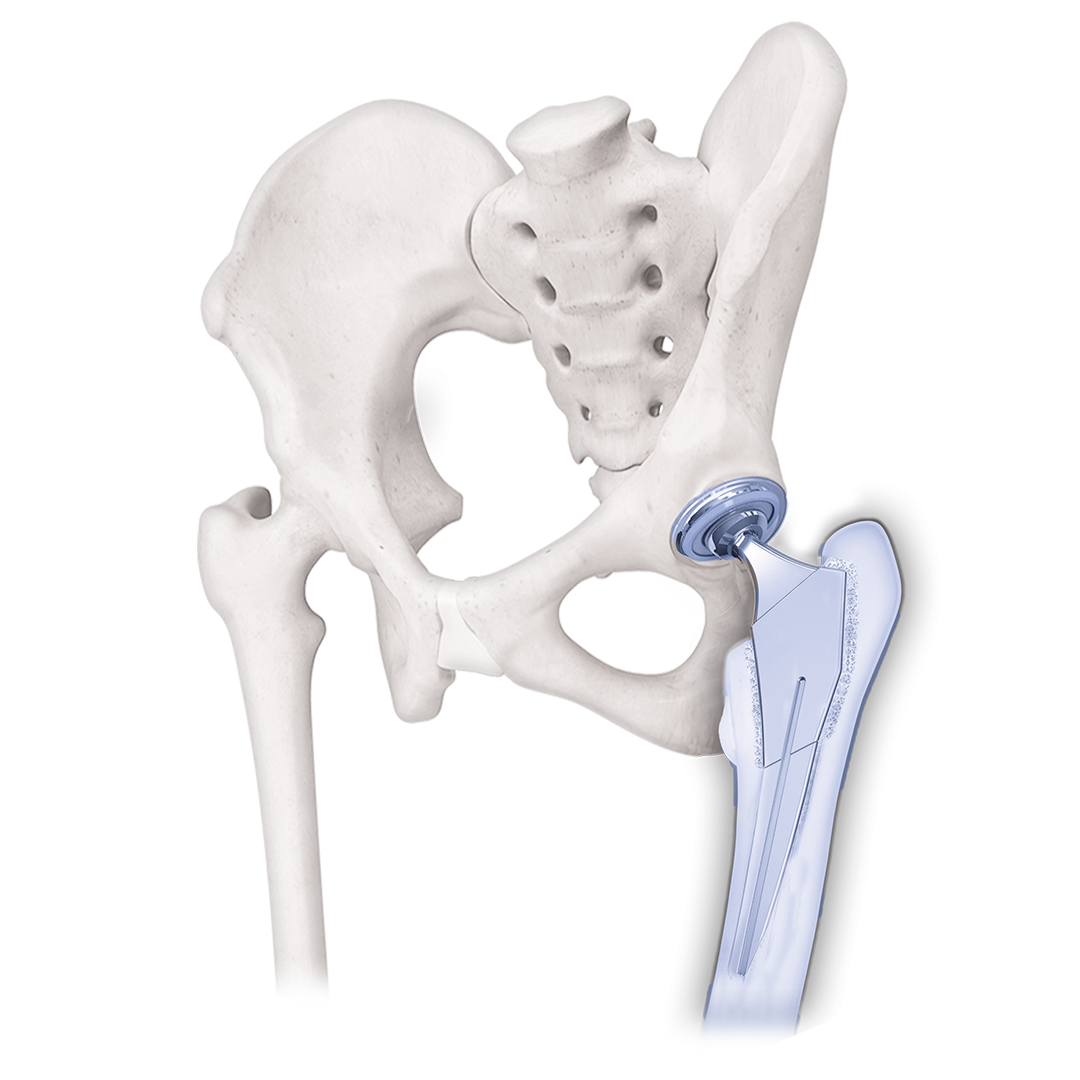

Joint Replacement

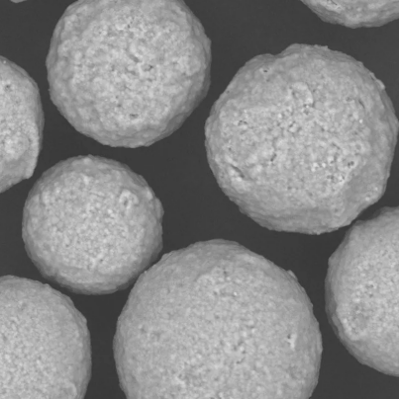

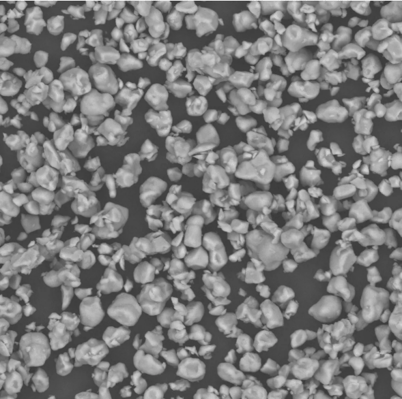

CAM Bioceramics’ powders are widely utilized in the orthopedic industry for implant coatings. Hydroxyapatite (HA) coatings play a crucial role in enhancing bone bonding. With our extensive experience in coating technology, we have developed customized calcium phosphate coating powders designed to meet the demands of even the most challenging implant applications.

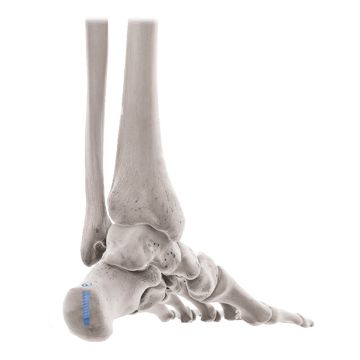

Resorbable Fixation

Calcium phosphates are commonly used in bioresorbable fixation devices, such as interference screws and suture anchors. Hydroxyapatite (HA) and β-TCP serve as bioresorbable, osteoconductive materials, often combined with resorbable polymers. As the calcium phosphates gradually resorb, they actively promote and stimulate bone growth.

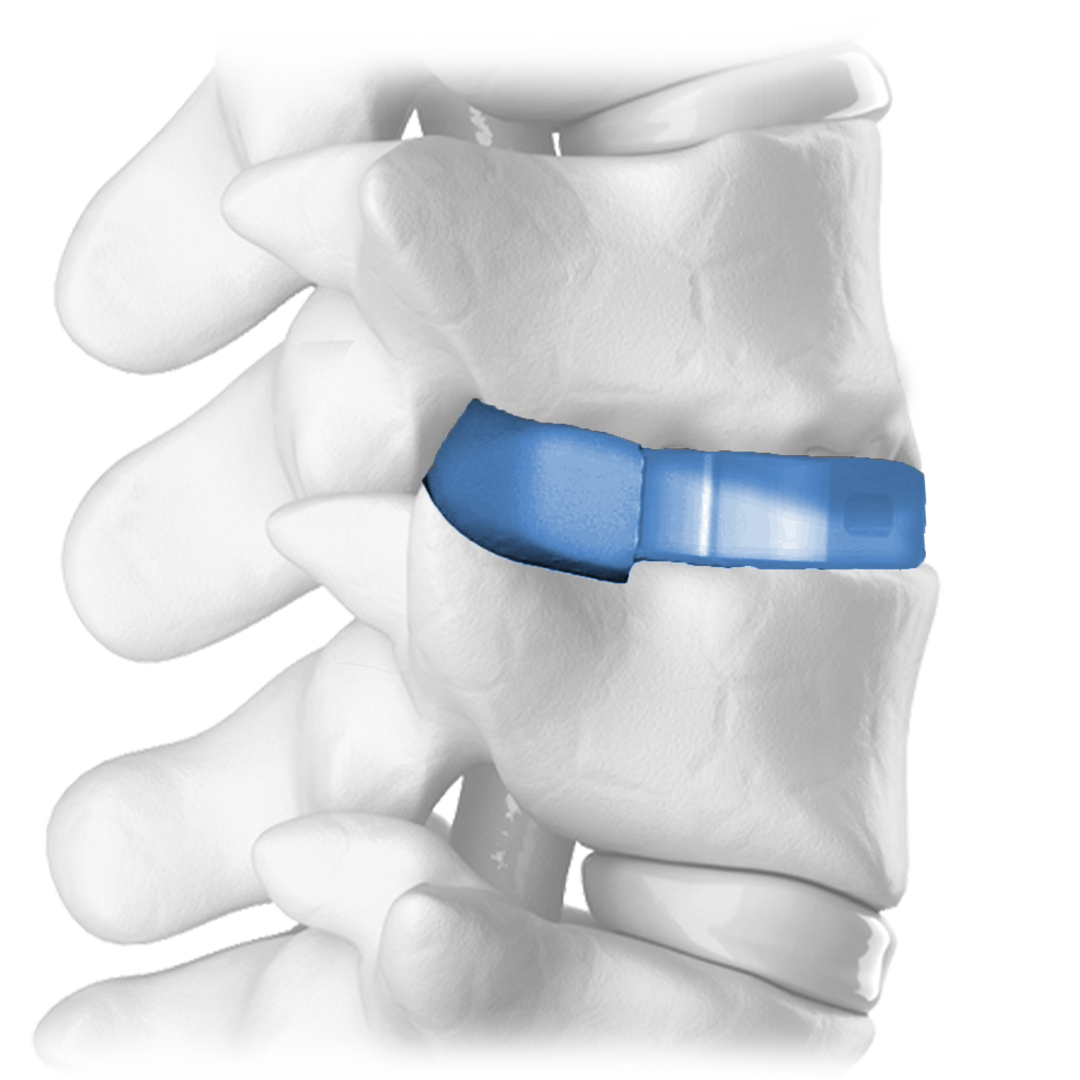

Spinal Repair

Our calcium phosphate products are ideal for spinal fusions due to their exceptional osteoconductive properties. These materials support bone growth and help create a strong bond between the vertebrae during the healing process.

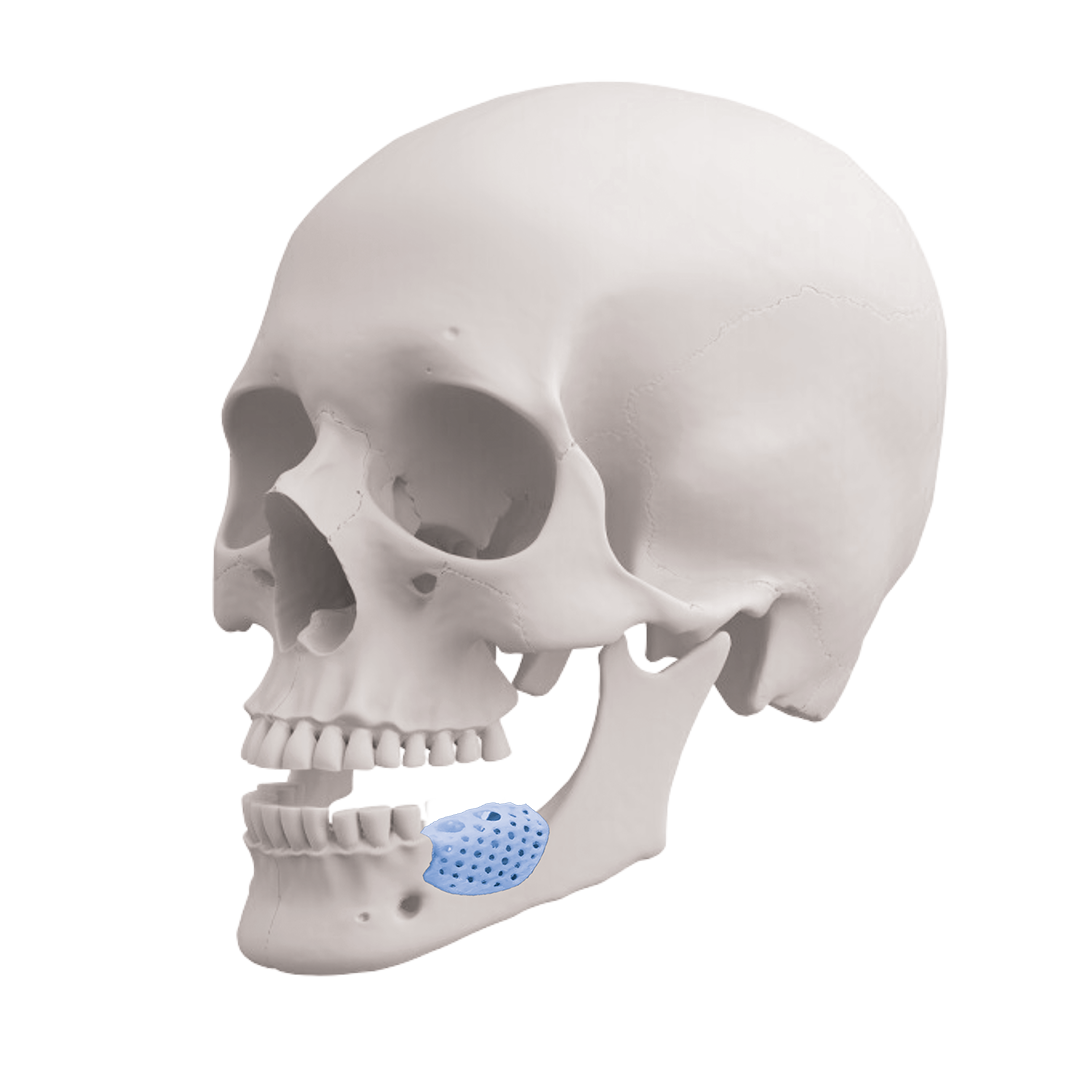

Additive Manufacturing

Calcium phosphate powders specifically engineered for the production of customized implants using a variety of additive manufacturing technologies.

Bone Void Fillers

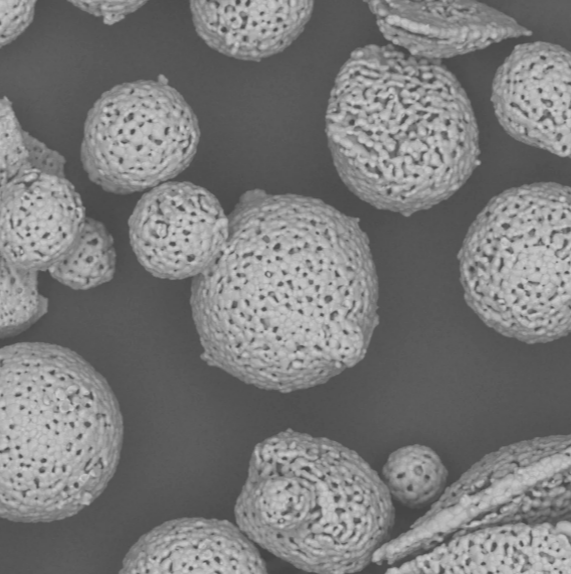

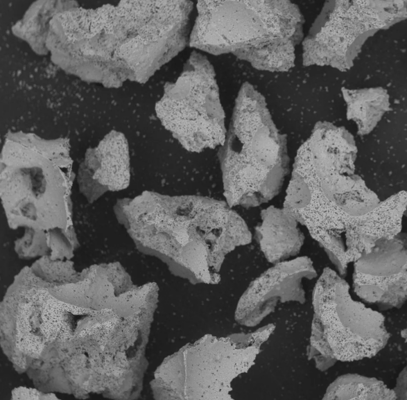

Our powders and granules are widely used in bone void fillers for applications such dental procedures and orthopedic surgeries to support the regeneration of lost bone tissue.

RESEARCH PAPER

Antimicrobial activity of ion-substituted calcium phosphates: A systematic review

The findings demonstrate that ion-substituted calcium phosphates hold great promise for the development of novel antibacterial materials. Download and read more.

Sustainable practices

Made in Holland

All CAM’s Calcium Phosphate products are designed and manufactured in-house, ensuring full control over quality and traceability.

In-house production

Our versatile production facility with four spray dryers allows for a wide range of production processes, enabling us to handle continuous scale production as well as smaller-batch production efficiently.

Custom-made craft products

With over 35 years of expertise in designing calcium phosphate products for all medical device markets, we are ready to tackle any challenge, delivering specialized solutions tailored to meet the unique needs of our customers.

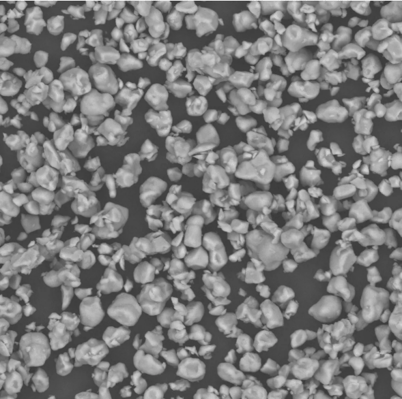

Customized Powders

Implant coating on metallic implants

3D printing, Bone cement used as bone void filler

Bone cement used as bone void filler

(Bio)resorbable implants (screws), Bone cement used as bone void filler, 3D printing

(Bio) resorbable implants (screws), Bone cement used as bone void filler, 3D printing

Granules used as Bone void fillers, Filler material (injectable putty)

.jpeg?width=407&height=400&name=image%20(2).jpeg)

Free Consultation for

Members

"Are you searching for a new coater or seeking insights for your new product development line? Learn more about our exclusive consultation, now available for Bonezone members."

ISO 13485:2016

Quality is a non-negotiable standard at CAM Bioceramics. Our in-process controls ensure full compliance with ISO 13485:2016, USP, and Ph. Eur standards. This commitment guarantees batch-to-batch consistency, providing our customers with reliable, high-performance biomaterials every time.

Scalability from Development to Production

At CAM Bioceramics, we understand the challenges of scaling from development to full production. Our powders and granules are developed using production-grade equipment—not just laboratory setups. This approach ensures seamless scaling without compromising on process validation or product quality. Whether you’re in the early stages of development or ready for full production, we have the capacity and expertise to deliver.